Melita Vilsone

Arturs Eižens Zalsters

Information obtained from The Jūrmala City Museum

The hull of Riga ship was built much like a hull of a large sea boat. It consisted of a keel, stems, outer casing, frame, stringers and internal planking. All these elements were made of oak. The cross-section of the 9340 mm long keel in its middle resembled the letter “T”, while in the ends gradually turned into a rectangle. Both of the stems resembled a tilted letter “L”. The cross-section of the lower part of the stems was much like a rectangle, while the cross-section of the tilted upper part – a trapezoid. The lower sections of the stem formed a continuation of the keel, thus the total length of the ship was 11400 mm. The lower sections of the stems were connected to the “real” keel with an inclined, vertically positioned 250 mm long joint. The upper part of the front stem formed a 58 degrees angle with the horizontal plane, the upper part of the rear stem – 70 degrees angle. The height of the front stem was 3150+150 mm, while the height of the rear stem – 2800+150 mm. Both the ends of Riga ship were damaged; therefore the height of the stems and the width of the upper boards had to be calculated. The total possible inaccuracy of the numeric values is within the limits of displayed tolerance.

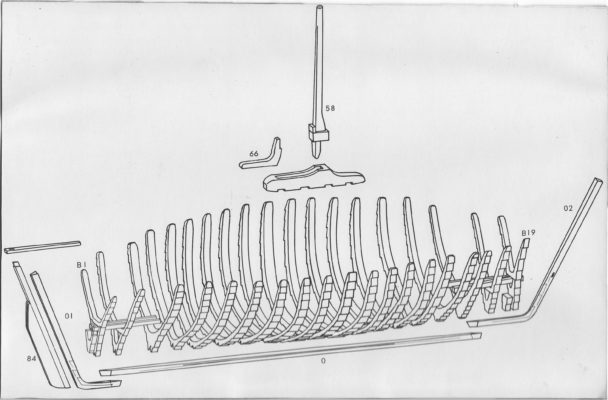

The placement of frames in Riga ship

The placement of frames in Riga ship

The labels in reference material are as follows: 0 for keel, 01 for rear stem and 02 for front stem. The total length of the ship, measured between the top of the stems reached 14390+150 mm.

The outer casing was made of 12 pairs of boards. The right side boards, counting from the keel, were labeled as N1-N12; the left side boards – M1-M12. The first pair of the boards (N1 and M1) was attached to the middle part of the keel with iron rivets, while forged nails were used to attach them to the ends of the keel and stems. The next pair of boards (N2 and M2) was attached to the previous pair with rivets, while the ends were attached to the stems with forged nails. All the other pairs of boards shared the same method of fastening. The boards were positioned in such a manner that they overlapped each other. The width of overlapping was approximately 60 mm. Casing that is made in such manner is called lapstrake or clinker method. The name “clinker” comes from the way the boards overlap each other, much like a tiled roof. The thickness of the boards was 25-30 mm, while in the ends, closer to stems, the thickness decreased to 18-20 mm.

To get the shape of a hull as it was intended to be, every pair of boards had to have a strictly definite form. The boards can relatively be divided into 2 groups – the first six pairs (N1-N6 and M1-M6) mostly contributed to the breadth of the hull, while the upper boards (N7-N12 and M7-M12) contributed mostly to the height.

In the areas where boards overlap and where boards meet the keel and the stems, seals had been fitted. The seals were made of tar impregnated linen and a substance, made of tar and cow hair.

Each board consisted of several parts that were fastened with the method of overlapping. In the interface of the joint the boards were thinner – approximately 15 mm. The outer casing of the ship in its middle part reached the height of 2400+100 mm (when measured from the lower surface of the keel), 2500+150 mm in the front and 2600+150 mm in the rear. The breadth of the hull in the middle part of the ship reached 4900+-100 mm.

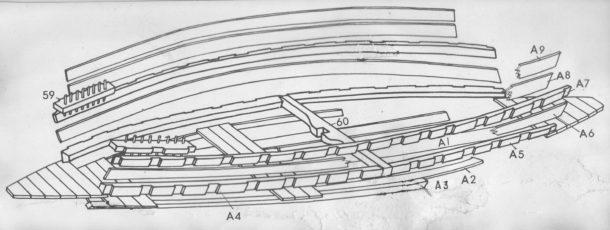

The placement of outer casing boards and stringers in Riga ship

The placement of outer casing boards and stringers in Riga ship

The hull of Riga ship has a peculiarity that needs to be explained in details. As mentioned before, the cross-section of the upper part of the stem had a shape of trapezoid. The sides of the trapezoid and, accordingly, the side face of the stem formed a narrow angle that increased towards the top of the stem. As each end of the boards was thoroughly fastened with forged nails to the side face of the stem, the ends of the boards formed some angle in relation to each other. The breadth of the hull of Riga ship exceeded 1/3 of the length of the ship. The angle between the boards near the stem was much too small to form a hull that wide. Therefore, when moving away from the stems, the angle between the boards had to increase rapidly. This means that each board, in relation to the longitudinal axis of the hull, formed a concave arc near the stem, and then was followed by a curved arc which again transfers to a concave arc when approaching the other stem. The aforementioned peculiarity is probably one of the trade secrets thanks to which the old craftsmen managed to endow the broad boat-like ships with speed and extraordinary steadiness in the restless sea.

The radioactive carbon dating analysis Ri-296, that was performed by experts from USSR Naval Science and Manufacturing Association “Soyuzmorinzhgeologija” of Ministry of Oil and Gas, showed that sample from the keel of Riga ship was 2750+-120 years old. The age of other components was significantly less. This implies that the keel was made from the so called “black oak” – an oak that was washed away by a river and had spent a long time in a damp environment. In late 19th century an old flat-bottomed boat was found in Turaida. According to publications, the most important components of the boat were also made of the black oak, while other components – from a rather fresh oak.

The boards for the outer casing and frame of Riga ship were made of a fresh-cut or briefly soaked oak. Most probably, a soaked tree was used, or one washed away by a river. According to a folk-song, fresh-cut wood was rarely used in boatbuilding:

Come, brothers, let’s go watch,

What tree in river flows.

The tree that in river flows,

Must be used to make a boat.

Only when the shell – the outer casing is ready, one would start to make and fit the frames. Riga ship had 19 main frames (B1-B19) and 2 small extra frames (B0, B20). The frames B1, B2, B18 and B19 were positioned differently than the main frames. Their bottom was made of large forked branches, shaped like letter “V”, while their tops resembled an open letter “U”. The frames were made like this because the frames B1, B2 and B18, B19 were used to fasten the rowing deck beam using a console. The frames B3 through B17 were V-shaped near the ends of the ship, and arc-shaped in the middle part of the ship. They consisted of several parts that were attached to each other with an inclined horizontally positioned joint. The outer surface of the frames had notches into which the boards of outer casing were fitted. The lower part, near the keel, had notches to drain the excess water. The frames were connected to the outer casing boards with oak pins. The diameter of the pins was 28 mm and one end was made broader. When the pin was hammered into place, the other end was expanded with a wooden wedge. The width of the wedge was equal to the diameter of the pin, thickness – several millimeters and height – about 50 mm. The frames B10 and B11 that were located near the jury mast knot have been repaired with birch. This means that prior to the crash in River Riga the ship had already suffered a crash. The cracks in the boards of outer casing indicate that the ship had a long lifetime. The cracks had been repaired with small pieces of oak wood and fastened with iron staples. If the crack was small it was pulled together with staples. The middle part of the staples was wider and thinner than the ends.

The photos from 1939 and the remains of the frames show that the frames had no beams (crossbars). The only exception is B11, which had a low placed beam (crossbar) for compensating the loads on the mast.

After the frames had been fastened, the inner casing boards and stringers were added. As the elements of the left side inner casing essentially are a mirror image of the right side elements, only the right side elements have been characterized in the description. The board A1, which was the closest to the keel, stretched from B8 to B17, not fully covering the later. A1 was made out of pine tree and was fastened to the frames with forged nails. The board A2 was fitted in similar manner and it reached from B3-B15. The board A3 was thicker than others because it supported the cargo deck. The A3 stretched from B3 to B12. Then came the main stringer that was made of oak and consisted of 2 parts – A4 and A5. Its cross-section had a trapezoid shape. The wide base of the trapezoid was oriented towards the frames and had 5-6 cm deep notches carved in it. The frames were fitted in these notches. The A4 reached from B3 to B11 but the A5 – from B5 to B17. The main stringer did not cover the frame B11 because opposite to it, between the A4 and A5, a 15 cm wide gap was kept. One end of the beam (crossbar) (No 60) of the frame B11 was pressed into the gap. The other end of the beam (crossbar) was pressed into the gap of the opposite main stringer. The stringers were fastened to the frames with long oak pins. In the same way as with the regular pins, these long pins had one wider end and a wedge in the other end. The pins had been hammered in turns – one from inside, one from outside. The pair of pins that were located beside was hammered simultaneously, because when hammered in together, the outer casing board, frame and main stringer pressed together. The board A6 reached from B3 to B17. It was made of birch and attached to the frames with forged nails. The upper stringer was made of oak. It reached from B3 to B17 as well. The stringer had 1cm deep notches where frames were fitted. The A7 was attached to the hull with oak pins. The board A8 was made of pine and reached from B14 to B16. The board A9 was made of birch. It reached from B4 to B17 and was attached with forged nails.

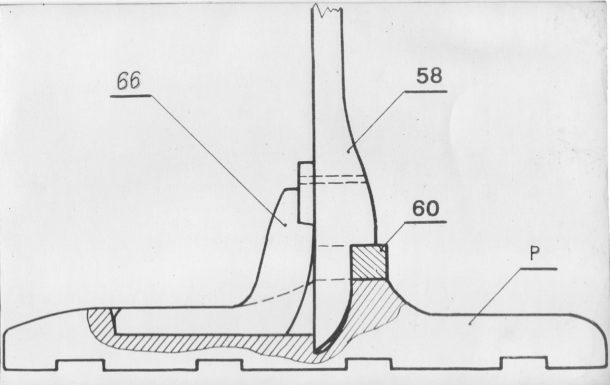

The components of the mast node of Riga ship

The components of the mast node of Riga ship

The crew alone could easily raise and lower the mast of Riga ship. The mast node consisted of the mast No 58, mast heel P and mast lock No 66, while beam (crossbar) No 60 and the mast heel P were fixed in the hull. To raise the mast one had to insert the lower part of the mast in the notch of the mast heel P and slide forward until it stops in the cavity of the notch – the step. When the mast had been raised and fitted in the notch of the beam (crossbar) No 60, the mast was fixed by inserting the mast lock No 66. When inserting the lock, first its upper notch was pushed under the cam of the mast and then the lower part was pushed in the notch of the mast heel P. When the mast was fixed, the mast shroud was attached to the component No 74 – 4 ropes, 2 in each side of the ship. The components No 74 had previously been attached to the boards N12 and M12 using ropes. The holes had been drilled near the frames B8, B10, B11 and B12. This means that each pair of shrouds was attached in 4 points. The point to which the shrouds were attached was defined by the position of the sail at the moment. The fifth rope for fixing the mast – the stay was fastened in the hole of the front stem 02.

Halyard fall has been threaded through an opening at the top of the mast and was used to raise the yard. A rectangular sail, about 40 m2 large, was attached to the stay. Braces – ropes for turning the stay and sheets – ropes that pull back the lower corners of the rectangular sail, were attached to the components No 59 at the end of the hull.

Riga ship was equipped with a rudder that was torn away when the ship crushed. A piece of rudder No. 84 and mounting elements in the stem 01 both suggest that a rudder existed.

The reconstruction drawings of the ship were drafted according to the descriptions and photos of the components found in 1939, as well as based on measurements and evaluations of the components that have remained till nowadays.

In 1939, when the ship was excavated and dismantled, the components were labeled in two ways:

- Teared-off or loose components were numbered in the order of discovery. A total of 115 components were counted. The key components were: the lower part of the mast No 58, the mast lock No 66, a piece of the rudder No 84 and a board from outer casing No 99. Only the component No 99 has survived till today.

- The components that were tightly fastened to the hull were dismantled and labeled with letters and numbers. As mentioned before, the elements of the inner casing were labeled with the letter A. The fairly well preserved inner casing boards A1, A2, A6, A8 and A9 from the unharmed side of the hull, as well as the main stringer A4&A5 from the cargo deck support beam A3 and the stringer A7 were dismantled in 1939. A piece of the beam A3 and the stringer A7, which broke into 3 pieces, can now be seen at the museum.

In 1939 the fully preserved small extra frames B0&B20, the lower V-shaped parts of the frames B1, B2, B18 and B19 (only fragments remained from the U-shaped parts) and the frames B3-B17 from the unharmed side of the hull were dismantled. It’s clear that the components of the frames B3-B17, which were located in the damaged side of the ship, were almost totally destroyed. However, it must be noted that a mirror image of the destroyed components still existed in 1939 and allowed to obtain a full notion about the ship’s Riga ship and frames back then. Luckily, both parts of the frame B9 from the middle part of the ship have been preserved till today. The frame B0, the lower V-shaped part of the frame B2 and fragments from several other frames can still be seen.

None of the outer casing boards that were dismantled in 1939 have been preserved. Merely a piece from a board that was found in the vicinity of the ship and labeled 99 can be seen at the museum.

Key components – the stems and the keel have been preserved till today. The lower part of the rear stem 01, as well as 8 boards form the upper part also still exist today. The lower part of the front stem 02 and 6 boards from the upper part are still intact. The top of both stems has been “gnawed” away – in those times the traffic in the River Riga (Rīdzene) must have been intense. The keel 0 is preserved in good shape, although broken in half.

One must also add that in 1984 samples were cut out from the keel 0 and stringer A7 for radioactive carbon dating analysis.